FAI first piece test equipment

- Product Name:FAI first piece test equipment

Characteristic:With the development of electronic manufacturing industry, today's SMT electronics factory patch element size and PCBA board density reached a hitherto unknown degree, product updates faster and faster, a number of models, small batch, frequent change more and more challenges of the plant's manufacturing capacity of high-speed SMT to enhance the plant's production capacity, but in SMT the first confirmed links, most still remain in the stage of manual confirmation backward. The first part confirmation has become one of the bottlenecks in SMT production, so our company pioneered the SMT high-speed intelligent first piece inspection equipment FAI-320M, greatly reducing the waste of manpower, time and quality.

With the development of electronic manufacturing industry, today's SMT electronics factory patch element size and PCBA board density reached a hitherto unknown degree, product updates faster and faster, a number of models, small batch, frequent change more and more challenges of the plant's manufacturing capacity of high-speed SMT to enhance the plant's production capacity, but in SMT the first confirmed links, most still remain in the stage of manual confirmation backward. The first part confirmation has become one of the bottlenecks in SMT production, so our company pioneered the SMT high-speed intelligent first piece inspection equipment FAI-320M, greatly reducing the waste of manpower, time and quality.

Characteristic:

1, automatic check impedance: use the probe to automatically determine L, C, R and check with the program to ensure the correct assembly of parts;

2, visual inspection: through the camera on the display of each part of the product, combined with the assembly of the direction of the logo, the shape of the text to confirm;

3, automatically generate detection procedures: by importing the BOM table or CAD file, automatically generated detection equipment running procedures. Generate data list: categories (C, R type), location, part code, assembly X/Y coordinates, parts size, part height, assembly angle, base value, lower limit value, upper limit value, action sign, printing character, check form;

4, report function: detection completed automatically generated reports, and equipped with detection process, image data, PCBA related information, the report can be archived, print, send mail;

5, other auxiliary functions: teaching mobile function, data recording function, display detection progress, video picture rotation function, two times confirmation function, with inquiry part height function, work end setting function.

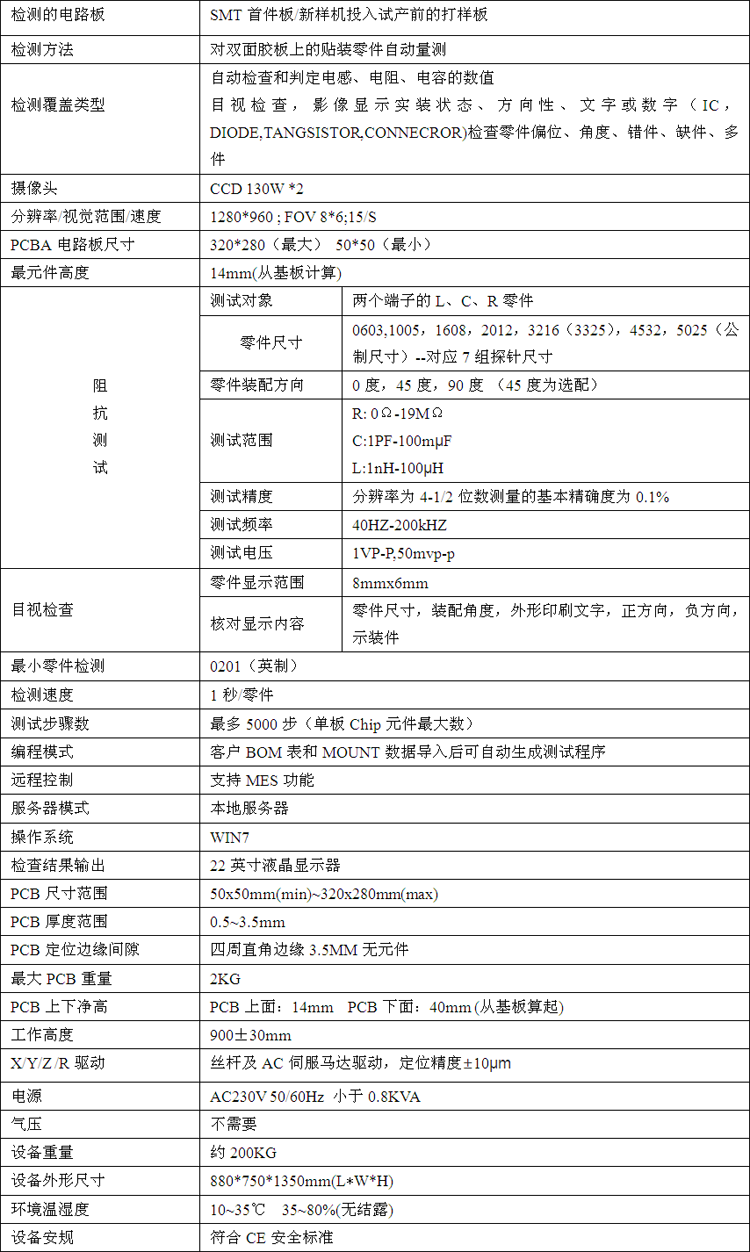

Product specification: