Ultrasonic spray system for wave soldering

- Product Name:Ultrasonic spray system for wave soldering

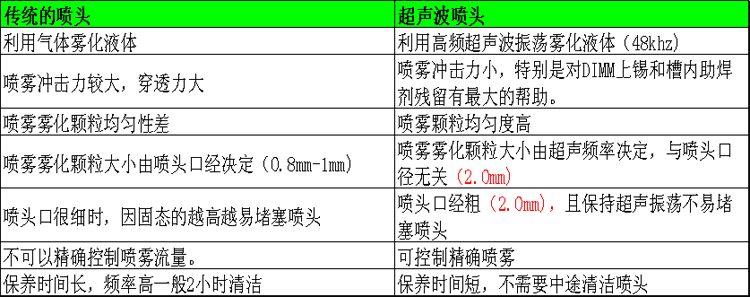

Characteristic:The new system of ultrasonic wave soldering replaces the traditional spray head which relies on the pressure and gas to crush the liquid into small particles. The ultrasonic spray head uses the lower ultrasonic vibration energy to carry out liquid atomization. The liquid can be sent to the spray head by self gravity or low pressure liquid pump, and can be continuously or intermittently atomized, so that the spraying effect is better and even. This section is mainly applicable to electronic manufacturing and processing industry, for DIP hand inserted parts on tin filling, welding quality, surface cleanliness, have greatly improved, while saving flux for enterprises to reduce the use cost.

The new system of ultrasonic wave soldering replaces the traditional spray head which relies on the pressure and gas to crush the liquid into small particles. The ultrasonic spray head uses the lower ultrasonic vibration energy to carry out liquid atomization. The liquid can be sent to the spray head by self gravity or low pressure liquid pump, and can be continuously or intermittently atomized, so that the spraying effect is better and even. This section is mainly applicable to electronic manufacturing and processing industry, for DIP hand inserted parts on tin filling, welding quality, surface cleanliness, have greatly improved, while saving flux for enterprises to reduce the use cost.

Characteristic

1. spray uniformity is higher, more stable, improve welding quality;

2. to improve the nozzle due to the solid content of Flux blockage, ultrasonic nozzle using 2.0MM nozzle with high frequency ultrasound, so as to stop the nozzle clogging, resulting in poor quality;

3. Panasonic servo motor control, can be programmed by software to control the speed of spray movement, and local spraying of flux, flexibility, high degree of operation;

4.Flux is more economical, the utilization ratio of raw material is high, and the cost is saved;

5. independent research and development of spray system, at the same time to FLUX flow and air pressure real-time monitoring adjustable;

6. system can be connected with the customer control computer or independent control (need the customer open communication port);

7. maintenance time is reduced, plate bottom cleaner.

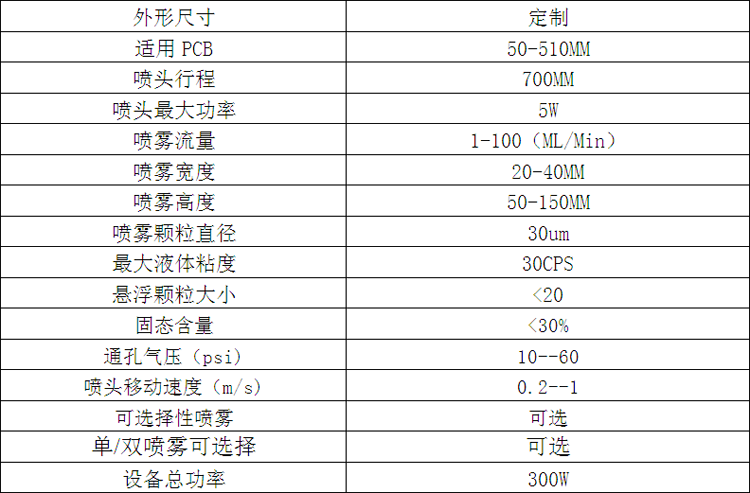

Product specification: