SMT has automatic feeding equipment for accessories

- Product Name:SMT has automatic feeding equipment for accessories

Characteristic:SMT automatic feeder is the head and tail of the same specification of 8MM two coil belt, automatic detection of empty material position, accurate cutting, automatic docking, and automatically wrapped with adhesive tape. Simple operation, greatly enhance the refueling time, save manpower, improve production efficiency, to solve customer problems caused by new employees to operate the production line equipment of micro stop to bring two times the cost of the loss of material quality; to control, production control.

SMT automatic feeder is the head and tail of the same specification of 8MM two coil belt, automatic detection of empty material position, accurate cutting, automatic docking, and automatically wrapped with adhesive tape. Simple operation, greatly enhance the refueling time, save manpower, improve production efficiency, to solve customer problems caused by new employees to operate the production line equipment of micro stop to bring two times the cost of the loss of material quality; to control, production control.

Characteristic:

1, simple operation: 10 minutes of learning can operate skillfully, no longer rely on skilled staff, reduce downtime, improve efficiency

;

2, save manpower: mobile operation, can realize the two line one person operation (specifically see customer line planning);

3, parts lossless: using optical fiber automatic detection of materials, automatic and accurate calibration of docking position, no loss of parts

;

4, material belt recycling: after the material is successful, the operation personnel long press material belt recovery button to realize automatic feeding, convenient and quick;

5, accurate and efficient: preparation parts each time the material is only about 8S can be completed, the success rate of up to 97%

6, equipment over the probability: material access machine pass rate of more than 97%

7, error proofing system: own material barcode scanning comparison error prevention (matching customer error proofing system docking)

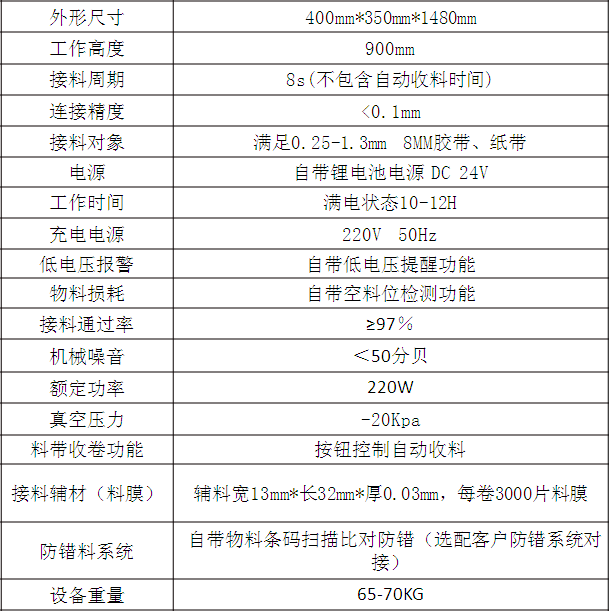

Product specification: